Ad-Solutions

More than just a supplier

AD-SOLUTIONS

More than just a supplier

A family, a mission: to effectively solve the problems faced by - perhaps for the first time - in this sector, providing aluminum components of the highest quality. Founded in 2004, the company AD Solutions is based on the great experience of the owners and the skills of the workers employed; that every day they work hard to make the best products, starting from this noble material. Having become a leading player in the aluminum processing, on a national and international field, AD Solutions is not limited to being a simple supplier, earning the role of a fundamental partner for the biggest industrial companies. In fact, the peculiarity of the company is that of being able to interface in the best way both with those involved in the construction of the matrix, and with those who produce the finished product, thus being able to count on an incomparable complete vision to take the client from conception of the project until its full completion.

WE WORK ONLY WITH THE MOST ADVANCED TOOLS

Innovative, always

Thanks to our innovative technological knowledge, the result of continuous research and development, our customers can count on products that are increasingly performing and precise. To fully satisfy the increasingly complex demands of the industries and to return the full functionality of the finished product, in fact, the highest skills are not enough it is therefore essential to be able to have on cutting-edge equipment and machinery, able to make the most of extruded aluminum.

WHY WE USE ALUMINUM

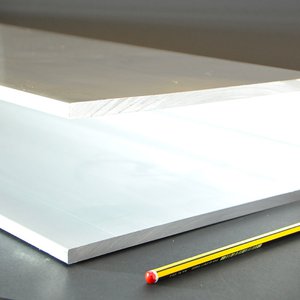

Resistant, light, ductile and infinitely recyclable: here are all the advantages of aluminum.

The growing preference of industries for this material is undoubted, so much so that aluminum, in terms of use, is now second only to steel. But why the aluminum? This material is extremely resistant, and this reliability goes hand in hand with a marked lightness, so as to make it suitable even for structures of a certain extent. It is then extremely ductile and workable, offering the concrete possibility of being extruded, forged, bent, laminated and fused. Unlike other metals, moreover, it can be fused and reused indefinitely, without losing any of its characteristics and properties: looking at its extreme recyclability, therefore, we can safely say that we are dealing with a sustainable metal for a responsible industry.

FROM THE EXTRUDED PROFILE FORWARD

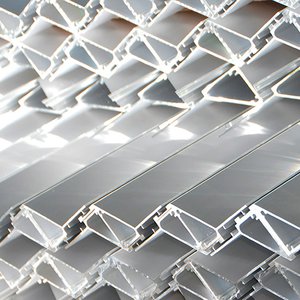

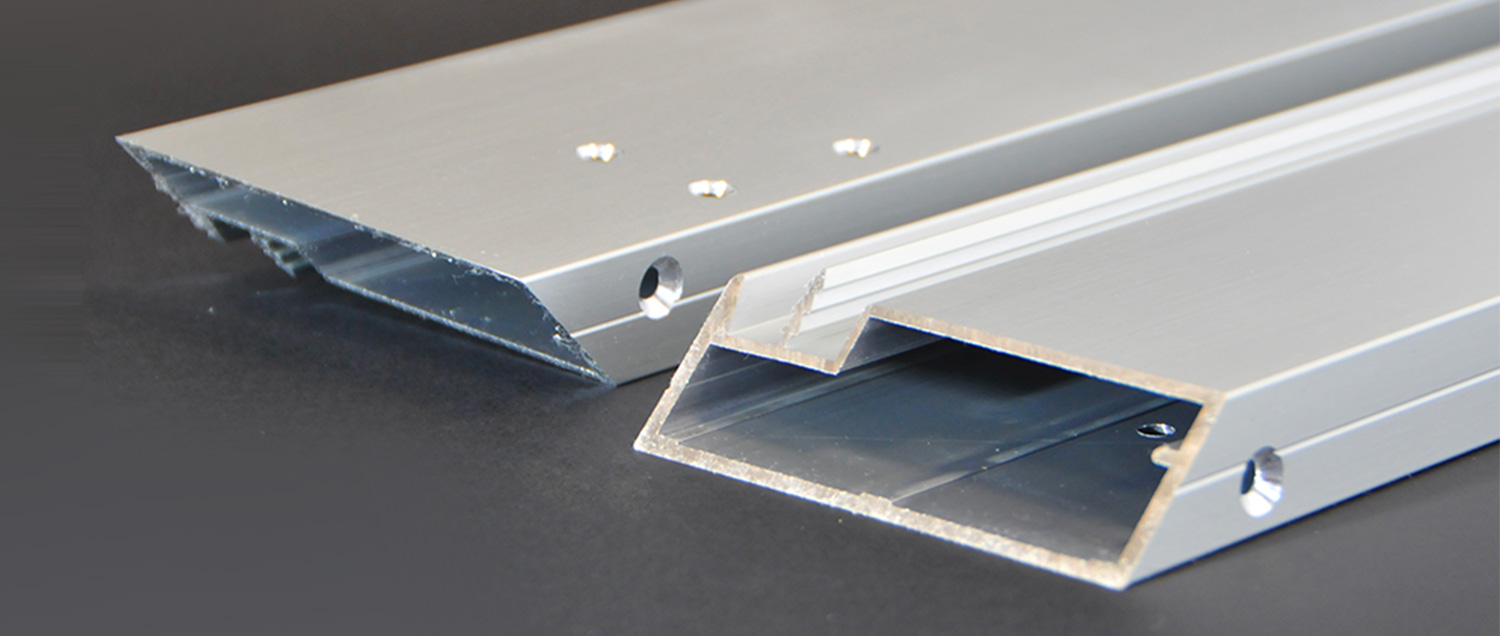

Our work, our passion

Our company presents customers from the most different sectors, from the naval to the furnishing, through construction and automotive. To meet the most diverse needs we can count on a wide and diversified range of profiles, from small and light sections to profiles with a decidedly important weight and dimensions. Our workers and our machines are therefore ready to work on any type of extruded profile, going to modify it to art following the project agreed with the customer. And that's not all: more and more often our customers take advantage of our collaboration also for the processes downstream of the semi-finished product, from the painting to the assembly, up to the packaging of the finished product.

AD SOLUTIONS s.r.l.

Via Leonardo Da Vinci, 4

30020 Torre di Mosto (VE)

P.IVA 03546670278

T +39 0421 303006

F +39 0421 30 63 99

info@ad-solutions.it

CONTENTS

HOME / WHO WE ARE / SERVICES / APPLICATION FIELDS / CASE HISTORY / CONTACTS / POLITICA PPQ ISO 9001

CERTIFICATION